Concrete Block and Precast & Ready Mix Producers:

Are you confused about what size and type concrete mixer you need for your operation?

One of the biggest mistakes you can make when choosing a concrete mixer is not choosing the correct size output production for your needs.

The second most common mistake is when producers choose the wrong type of concrete mixer for their application. It can be costly to your bottom line, unless you understand the types that are best for you.

Choosing a concrete mixer is like mixing cookie dough in the kitchen.

Making good cookies requires consistency and proper mixing of all the ingredients. Just like when you are in the kitchen, you can use different types of blenders and mixers to mix different materials. You should also use different mixers in the concrete industry. And the right choice depends on what you want to do.

Need help determining which method of materials measuring is best for your concrete mixer application?

If you don’t size the concrete mixer properly, then it will cost you money and lost profits for years in slowing down your operation. There are many considerations such as material input and output times along with the proper amount of mixing time of your materials.

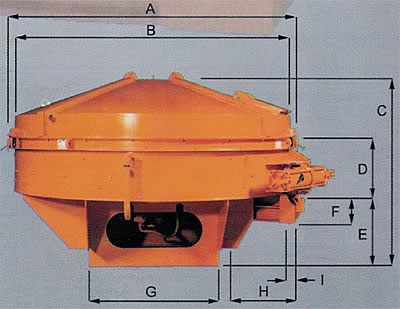

Turbine Concrete Mixer

Is a turbine concrete mixer is right for you?

You should be looking at a turbine concrete mixer if your requirements are more simplistic and your budget is a factor. Your requirements would generally be looking to mix materials in a fast manner with great consistency. Oftentimes, you may not know much about the quantity building requirements that would affect you when installing such a concrete mixer.

Model |

A |

B |

C |

D |

E |

F |

G |

H |

I |

|---|---|---|---|---|---|---|---|---|---|

| R500 | 6'10" |

6'7" |

5'5" |

20" |

24" |

10" |

34" |

22" |

4 1/8" |

| R1000 | 9'3" |

8'11" |

6' |

21" |

26" |

10" |

4' |

28" |

4 1/8" |

| R1500 | 11'3" |

10'10" |

6'3" |

25" |

29" |

10" |

4'6" |

28" |

4 1/8" |

| R2000 | 12'8" |

12'3" |

6'3" |

25" |

28" |

14" |

4'7" |

36" |

4 1/8" |

| R3000 | 12'8" |

12'3" |

7'7" |

31" |

33" |

14" |

4'8" |

36" |

4 1/8" |

| Model | Input Capacity | Output Capacity | Output per Hour 40 Batches | Output per Hour 50 Batches | Output per Hour 60 Batches | Motor Power | Number of Mixing Tools | Net Weight |

|---|---|---|---|---|---|---|---|---|

| R500 | 1.25 cu yd |

1 cu yd |

40 cu yd |

50 cu yd |

60 cu yd |

30 hp |

5 |

5380 lb |

| R1000 | 2 cu yd |

1.5 cu yd |

60 cu yd |

75 cu yd |

90 cu yd |

50 hp |

7 |

9370 lb |

| R1500 | 3 cu yd |

2 cu yd |

80 cu yd |

100 cu yd |

N/A |

75 hp |

9 |

14,000 lb |

| R2000 | 4 cu yd |

3 cu yd |

120 cu yd |

N/A |

N/A |

100 hp |

10 |

15,680 lb |

| R3000 | 6 cu yd |

4 cu yd |

160 cu yd |

N/A |

N/A |

150 hp |

10 |

18,632 lb |

Main features include: |

Production of the following products: |

Planetary Concrete Mixer

Producers who have concrete planetary mixers are generally looking to mix materials in a fast manner and utilize the multiple gates for color segregation using multiple hoppers. You would like the feature of being able to easily clean the inside of the concrete mixer with its totally open floor design and optional washout system.

Model |

Input Capacity |

Output Capacity |

||||

RP375 |

|

|

||||

RP500 |

|

|

||||

RP750 |

|

|

||||

RP1000 |

|

|

||||

RP1500 |

|

|

||||

RP2000 |

|

|

||||

RP3000 |

|

|

Main features include: |

Production of the following products: |

Spiral Blade Concrete Mixer

You would normally consider this type of concrete mixer in smaller output applications, and it’s best often used in dry cast concrete applications. Your budget would be smaller than if you were considering a turbine or planetary concrete mixer. Producers are generally looking for a lower budget startup cost.

Model |

Output Capacity |

Average Cycle Time Minutes |

Motor Drive HP |

Empty Weights |

Charging Heights |

||

cu. ft. |

cu. yds. |

cu. mtrs. |

|||||

8 |

8 |

0.30 |

0.23 |

4 |

10 |

2,000 |

42 |

16 |

16 |

0.59 |

0.45 |

4 |

20 |

3,500 |

45 |

30 |

30 |

1.11 |

0.85 |

4 |

30 |

5,000 |

58 |

50 |

50 |

1.85 |

1.42 |

4 |

40 |

8,500 |

68 |

80 |

80 |

2.96 |

2.27 |

4 |

60 |

15,250 |

77 |

100 |

100 |

3.70 |

2.83 |

4 |

75 |

24,150 |

77 |

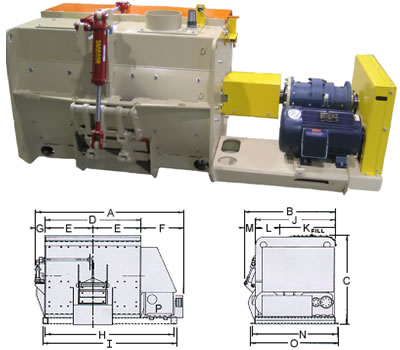

Twin Shaft Concrete Mixer

Producers that use Twin Shaft Concrete Mixers are normally companies that require large quantities of concrete material mixed in a very short time period. The most common applications for the twin shaft would include pre-stress and ready mix concrete producers.

THE CONCRETE MIXING CYCLE

Although the total cycle time is dependent on the speed at which the charging takes place as well as the type of concrete being produced, typically a concrete batch of wet cast or ready-mix concrete can be produced in less than 90 seconds. Note that adding some admixtures may require extra mixing time. The diagram below assumes that the aggregates are waiting in a skip or concrete holding hopper, ready for discharge. Note the premix time before water is added; this is essential to proper mixing and fast mixing times. The short total cycle time allows many plants to be upgraded to give double the output by replacing the mixer only, compared with adding a second mixer, which requires extra conveyors, chutes, holding hoppers and often an increase in elevation of bins and weigh hoppers.

Wet cast cycle (typical). Dry cast is not shown; we recommend Planetary for all dry cast applications.

| Charge aggregates | 5 sec | Refill | |||||||||

| Charge cements | 15 sec | Refill | |||||||||

| Premix time | 20 sec | Premix | |||||||||

| Charge water | 20 sec | Refill | |||||||||

| Charge admixes | Air | Other | Refill | etc. | |||||||

| Final mixing time | 20 sec | ||||||||||

| Discharge time | 8 sec | ||||||||||

| Door close | 2 sec | ||||||||||

| Total cycle time | Beginning to end = 90 seconds | ||||||||||

Ready to determine which size concrete mixer is right for you?

Just send me an e-mail with the amount of material required per hour or day for your concrete operation.Or pick up the phone and call me, Bill Fleming, at 913-766-1025. I will get back in contact with you within 48 hours.

You need to know which of the four types of concrete mixers fits your application, so you can maximize your profits and efficiency. You have many capacity sizes to choose from in determining the amount of material mixed per batch cycle. Ready to know which concrete mixer type is best for you? Click contact Bill Fleming to get the answers.